Componentes principales de una línea de producción de envases de alta eficiencia

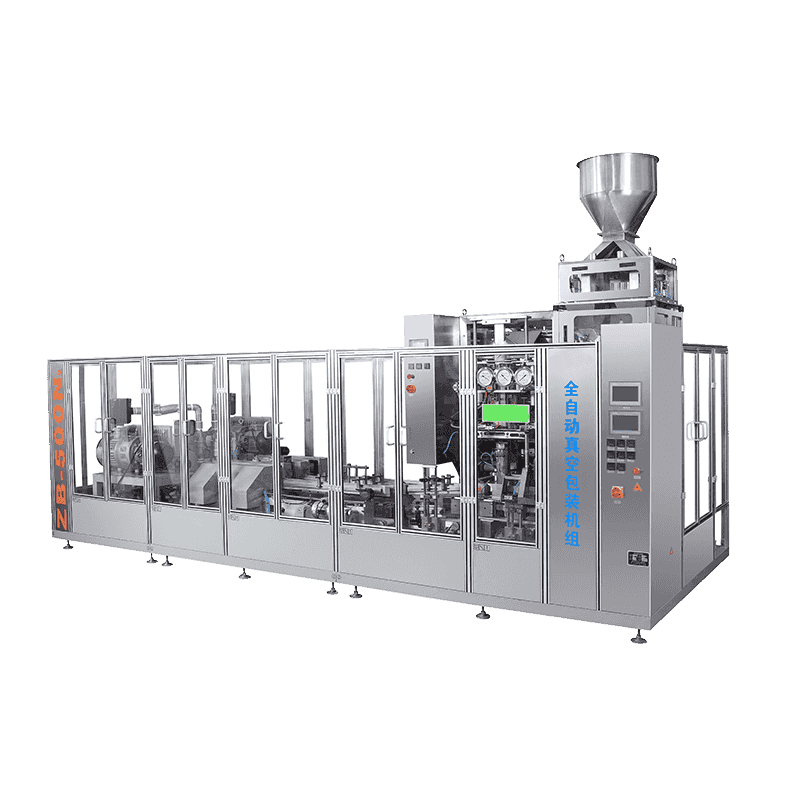

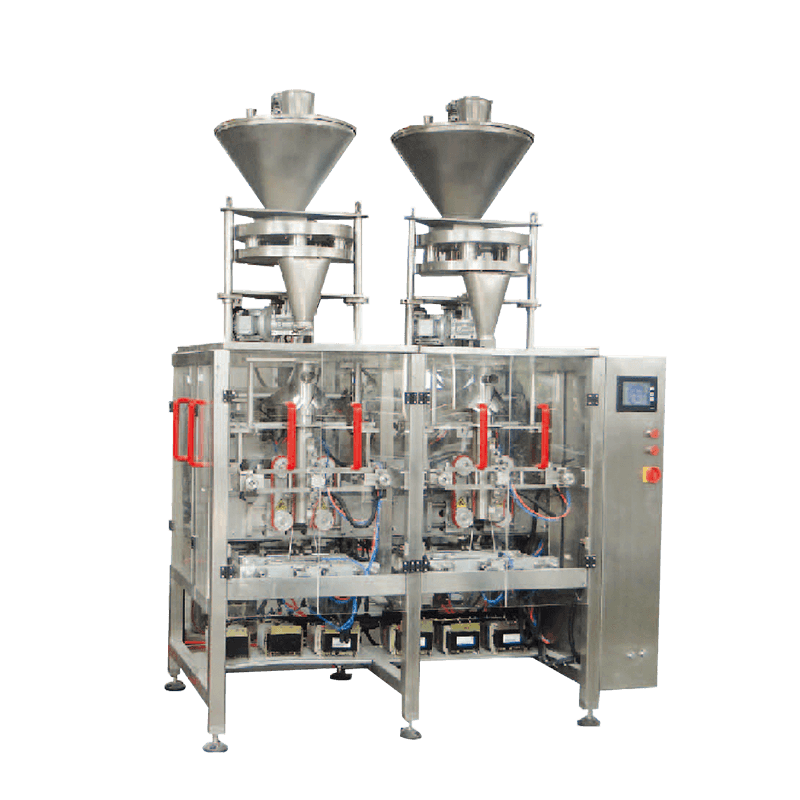

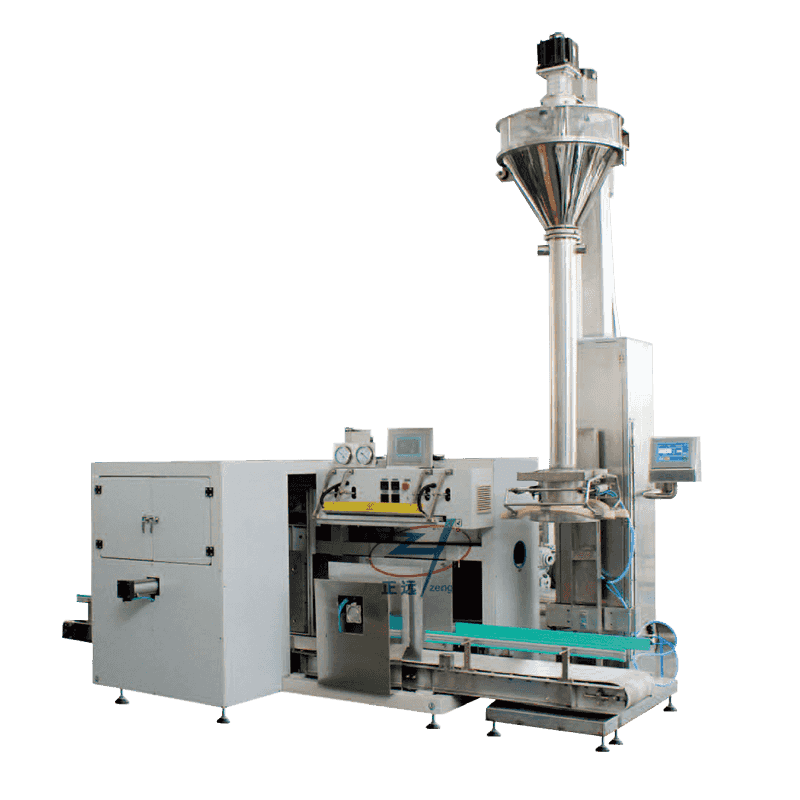

Un moderno línea de producción de envases es un ecosistema sofisticado de maquinaria interconectada diseñada para transformar productos a granel en unidades listas para el mercado. La base de este sistema comienza con los equipos de envasado primario, como las máquinas de formado, llenado y sellado vertical (VFFS) o llenadoras de bolsas rotativas, que manejan el contacto directo con el producto. Estos están respaldados por sistemas de pesaje de alta precisión y pesadoras de cabezales múltiples que garantizan la precisión de la dosificación, lo que reduce el desperdicio de producto y mantiene el cumplimiento normativo. La integración entre estos componentes es crítica; un cuello de botella en la etapa de pesaje puede detener todo el proceso posterior, lo que hace que los protocolos de comunicación sincronizados sean esenciales para mantener un flujo constante.

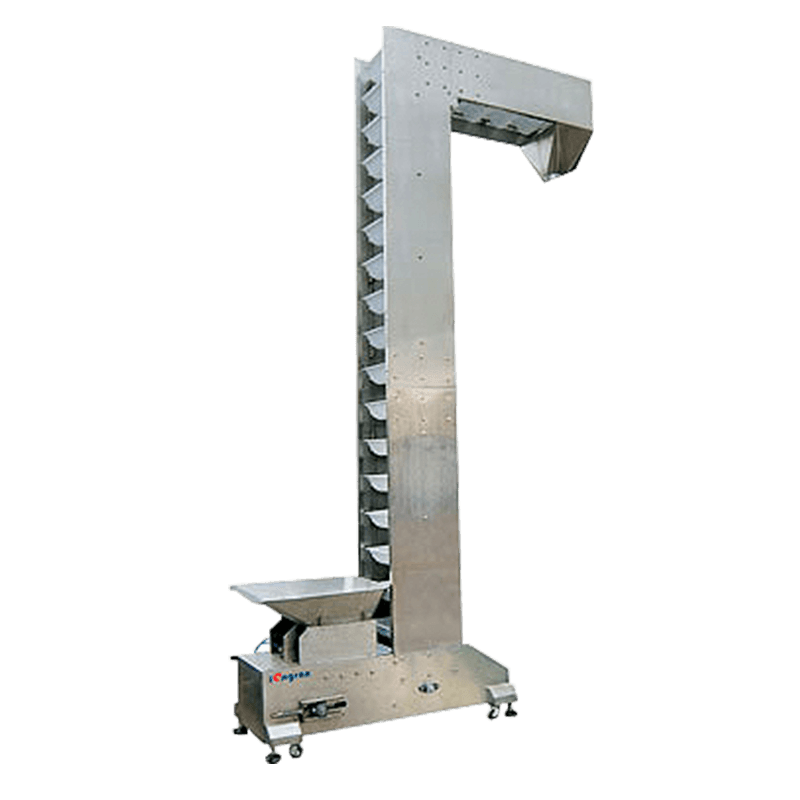

Las etapas secundaria y terciaria implican el encartonado, el revestimiento y el paletizado. El embalaje secundario se centra en agrupar unidades individuales en cajas listas para la venta al por menor, mientras que el embalaje terciario prepara estas cajas para el transporte a granel. Las líneas modernas suelen utilizar integradores de brazos robóticos para el paletizado, que ofrecen una flexibilidad mucho mayor que los paletizadores mecánicos tradicionales. Estos robots se pueden programar para manejar varios tamaños de SKU y patrones de apilamiento, lo que permite a los fabricantes cambiar entre líneas de productos con un tiempo de inactividad mínimo. La transición fluida entre estas etapas es lo que define un entorno de producción de alto rendimiento.

Especificaciones Técnicas para Equipos de Línea

Al seleccionar equipos para una línea de envasado, la compatibilidad técnica y la capacidad de rendimiento son las principales métricas para el éxito. La siguiente tabla describe las expectativas de rendimiento estándar para maquinaria clave dentro de un entorno de producción de volumen medio a alto:

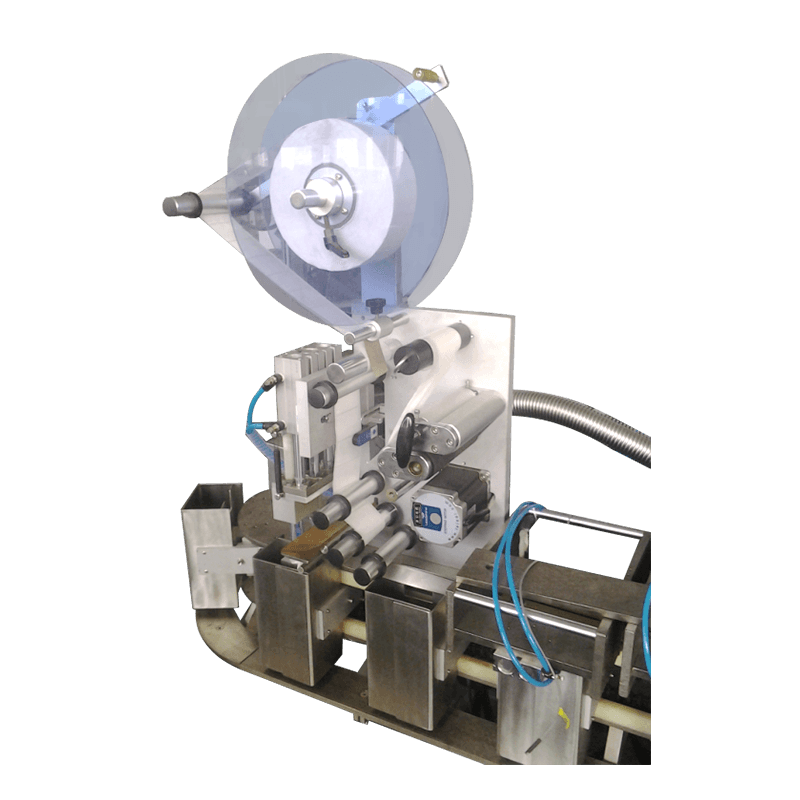

| Tipo de máquina | Velocidad promedio (BPM) | Métrica clave |

| Llenadora de líquidos rotativa | 120 - 400 | Precisión de llenado (±0,5%) |

| Sellador por inducción | 60 - 200 | Integridad del sello hermético |

| Etiquetadora automática | 150 - 500 | Precisión de colocación |

| Montador de cajas | 15 - 30 | Consistencia de la cuadratura |

Implementación de inspección y control de calidad inteligentes

El control de calidad ya no es un proceso de muestreo manual sino una necesidad automatizada en línea. Los sistemas de inspección por visión ahora son estándar en las líneas de alta velocidad para verificar la orientación de la etiqueta, la legibilidad de la fecha de vencimiento y el torque de la tapa. Estos sistemas utilizan cámaras de alta velocidad y software impulsado por IA para identificar defectos en milisegundos, activando brazos de rechazo neumáticos para eliminar los artículos defectuosos sin ralentizar la línea. Esto garantiza que solo los productos 100% compatibles lleguen a la etapa de carcasa, lo que reduce significativamente el riesgo de costosas retiradas del mercado minorista.

Puntos críticos de inspección

- Detección de metales y rayos X: escaneo en busca de contaminantes físicos dentro del producto después del sellado.

- Control de peso: Verificar que cada paquete cumpla con los requisitos de peso indicados en la etiqueta.

- Verificación OCR: Garantiza el reconocimiento óptico de caracteres de códigos de lote y fechas de caducidad.

- Inspección de sellos: uso de imágenes térmicas o sensores de presión para detectar fugas en envases flexibles.

Estrategias para minimizar el tiempo de inactividad durante el cambio

En una instalación de múltiples productos, la metodología de "intercambio de matrices en un solo minuto" (SMED) es vital para mantener la rentabilidad. Una línea de producción de envases que tarda cuatro horas en cambiar de una botella de 500 ml a una de 1 litro representa una pérdida enorme de ingresos potenciales. Para combatir esto, los fabricantes están invirtiendo en maquinaria "sin herramientas" donde los ajustes se pueden realizar mediante manivelas con lecturas digitales o mediante ajustes preestablecidos de HMI (interfaz hombre-máquina) que ajustan automáticamente los anchos del transportador y las alturas de los sensores.

El diseño de líneas modulares es otra solución práctica. Al utilizar unidades de equipos móviles que pueden entrar y salir de la línea con ruedas, las instalaciones pueden evitar ciertas máquinas o cambiar los cabezales de etiquetado en minutos. La estandarización de los acabados del cuello de los contenedores y las dimensiones de las etiquetas en diferentes gamas de productos simplifica aún más los requisitos mecánicos de un cambio. Cuando estas estrategias se combinan con un equipo de mantenimiento capacitado estilo "equipo de boxes", los tiempos de cambio a menudo se pueden reducir en más del 50%, lo que aumenta directamente la eficacia general del equipo (OEE) de la planta.

El papel de la digitalización y la IoT industrial

La integración de sensores de Internet industrial de las cosas (IIoT) en toda la línea de envasado permite la recopilación de datos en tiempo real y el mantenimiento predictivo. En lugar de esperar a que falle un motor, los sensores monitorean las vibraciones y las señales de calor para predecir fallas antes de que ocurran. Estos datos se introducen en un sistema SCADA (control de supervisión y adquisición de datos) centralizado, que proporciona a los gerentes una vista del panel del rendimiento de la línea, incluidas las causas del tiempo de inactividad y las tasas de desperdicio. Este nivel de transparencia es esencial para la mejora continua y ayuda a identificar ineficiencias sutiles que de otro modo podrían pasar desapercibidas para los operadores de sala.

English

English عربى

عربى

Contáctenos